Black Rock provides structural elements with architectural impact. At the same time we save owners cost and cut installation time.

At Black Rock we have our own professional trucking fleet of 15 tractors and 40 trailers, which means we can assure on-time building column deliveries. We can also tap into a network of over-the-road trucking partners to meet peak customer demands

Black Rock assures on-time deliveries by maintaining our own trucking fleet of 15 tractors and 40 trailers. We also tap into our network of over-the-road trucking firms whenever needed to meet owner demands.

Steel column fire protection product costs

Based on a 9 × 9 Column @ 12′ Tall (Open shop rates)

| Sheetrock Encased, 2 HR | Intumescent Coatings, 2 HR | Spray Fireproofing as per UL X716 enclosed in a column cover | Concrete Encased, 2 HR | BRFC “BRIDGEPORT” TYPE SS X106, 2 HR | |

|---|---|---|---|---|---|

Labor | $189 | $555 | $108 | $480 | $273 |

Material | $207 | $562 | $103 | $600 | $350 |

Equipment | $14 | $71 | $13 | $42 | $27 |

Column cover | —– | —– | $1,575 – $2,205 | —– | —– |

Onsite lost time | —– | Three Days+ Special Inspection | —– | —– | No Days Lost |

Total Initial Cost | $410 | $1,188 | $1,800 – $2,430 | $1,122 | $650 |

| *Cost Estimate created with 2018 Building Construction Costs based on RSMeans Data opens in a new windowwww.rsmeans.com |  |  |  |  |   |

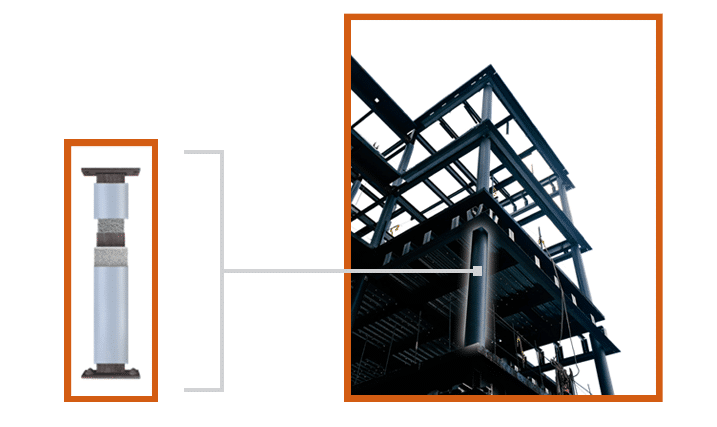

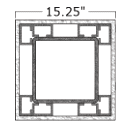

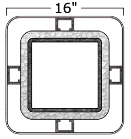

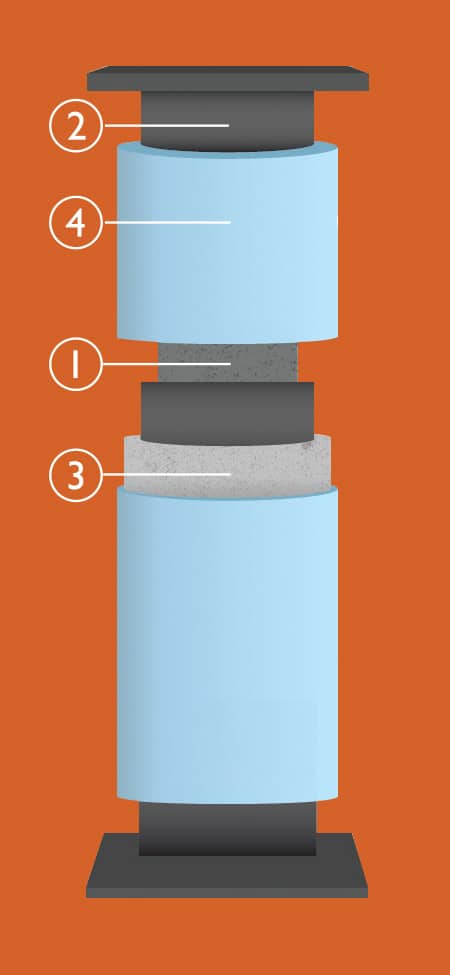

The diagram shows (1) Concrete (2) Structural Steel (3) Vermiculite Fireproofing, a special proprietary insulating material (4) Outer steel shell that permanently protects the fireproofing material.

Black Rock Fireproof columns are rated and labeled by Underwriters Laboratories, Inc. for fire retardant classifications of 2, 3 and 4 hours. Columns are completely shop fabricated and shipped to the job site ready to erect.

Look to Black Rock as the manufacturers who specialize in fire proofing steel columns. We design, manufacture, and deliver the columns that capture the vision of architects, deliver on cost and integrity for engineers, and support the structures that delight occupants.

XThe accessibility of our website is taken very seriously. We strive to meet WCAG 2.1 AA Web Accessibility standards by routinely evaluating our website using automated evaluation tools and manual testing when required. As content changes we review and correct issues and are responsive to our users needs. If you encounter issues with our website, please report them so they may be corrected in a timely manner.